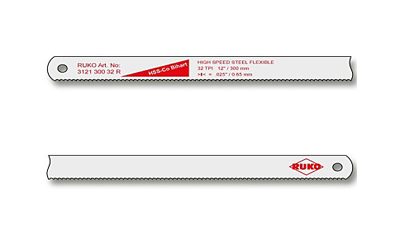

Hack Saw Blade Suppliers In Dubai

Hand hacksaw

blades are a conventional cutting instrument used to cut metal and non-metal

materials. There are applications for this in the home and artisan workshops.

Carbon steel, high-speed steel, and bi-metal material are the three steel types

used to make blades. The extensive product selection available at Aatco General

Trading LLC hack saw blade suppliers in

Dubai lets you choose the blade best suited to your requirements.

The bi-metal

hand hacksaw blade available on the market are made from M2-grade steel. These

blades have excellent characteristics because they combine these two materials,

which ensures their durability. A spring steel band has a component made of HSS

that has been laser-welded to it. This link results in the blade having

increased flexibility, toughness, and body plasticity while producing high

levels of tooth abrasion resistance. Appropriate for cutting a variety of

materials, in particular, hard steels with a tensile strength of up to 1100

N/mm2. BiM blades have a long lifespan and make cutting easy and fluidly

possible while requiring little effort.

The teeth on the

blades are formed of a tempered HSS carbon steel strip

that makes up the blade. The application of heat treatment results in the

formation of longitudinal regions with varying degrees of hardness. After the

teeth that have a hardness of 62-65 HRS, various places have a hardness that

steadily decreases. The blades have exceptional flexibility because of the heat

treatment procedure used on them.

Appropriate for

cutting various materials with a maximum steel hardness of 700 N/mm2.

High-speed steel ensures accuracy, smoothness, and safety when sawing while

also making for a blade that lasts incredibly long.