Techniques and Tools for Precision Engineering

One of the deburring blade suppliers in Dubai, AATCO believes that accuracy engineering depends significantly on precise measurements to provide the highest degree of accuracy in production operations. In this part, we will look at several cutting-edge measuring tools and methods that have transformed the area of precision engineering.

Coordinate Measuring Machines (CMMs).

Coordinate Measuring Machines (CMMs) are frequently employed in precision engineering due to their ability to correctly measure complicated geometry. These devices use a probe to gauge different locations on an item, resulting in a digital depiction of its form. Engineers may assure precision by comparing the measured information to the planned design and making required modifications.

Laser interferometry

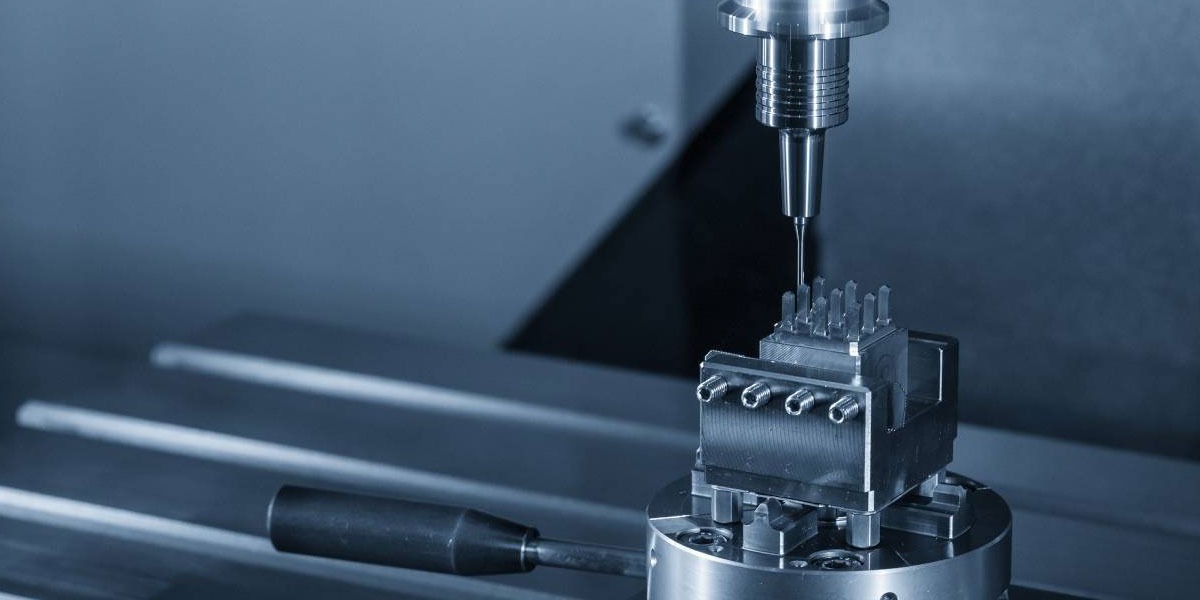

Laser interferometry is a technology that uses laser beam interference patterns to determine distances with high accuracy. Engineers can precisely discern minute shifts in the location of a target by splitting a beam of laser light and directing it at it. This method is very effective for determining the efficiency of precision devices like CNC milling equipment or optical systems.

Optical Profiling

Optic profilometry is a non-invasive method that measures an object's surface topography. Engineers can acquire very precise 3D surface profiles by beaming a structured illumination pattern onto an object and measuring its deformation. This technology is important in sectors that need high surface roughness and accuracy, such as aerospace and semiconductor production.

Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is a computer approach for simulating the behaviour of complicated structures under different situations. Engineers can forecast how a structure will behave to varied loads and pressures by breaking it down into smaller pieces and modeling its behaviour using mathematical equations. FEA allows engineers to optimise designs for optimal precision and durability, eliminating the need for expensive physical prototypes.

Case Study on Precision Milling in the Automotive Sector

To demonstrate the significance of precision engineering, take a case study from the car sector. Even minor deviations in the production of engine components like pistons and cylinder heads can result in catastrophic failures.

Tips for Improving Precision in Engineering discussed by one of the concrete drill bit suppliers in Dubai, famous as AATCO:-

To guarantee accuracy, calibration, and maintenance of measurement instruments should be performed regularly.

Implement procedures for quality control throughout the production process.

Invest in staff training to improve their knowledge of precision engineering concepts.

Strive for continuous improvement through input and information analysis.

Adopt new technology and keep current on the latest advances in precision engineering.

Summary

Tools such as optical profilometry and finite element analysis allow engineers to optimize designs for optimal performance. Following these guidelines and using precision engineering concepts allows companies to provide products that satisfy the most stringent accuracy and reliability criteria.